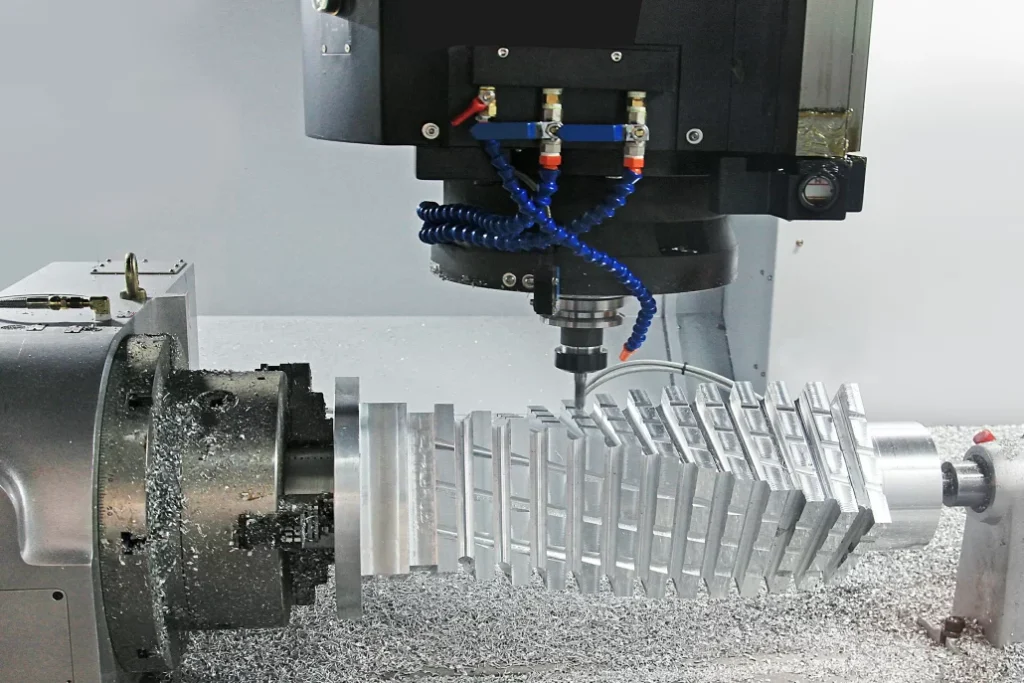

CNC precision machining stands at the forefront of modern manufacturing, consistently delivering exceptional quality with every cut, hole, or groove it produces. This technology embodies the perfect blend of accuracy, efficiency, and reliability, enabling manufacturers to achieve results that surpass traditional methods. The essence of CNC machining lies in its ability to precisely control tool movement, ensuring that every detail meets stringent specifications without compromise. This level of precision guarantees that components fit perfectly, function flawlessly, and maintain uniformity across production runs. Whether producing complex aerospace parts, intricate medical devices, or custom automotive components, CNC precision empowers industries to push the boundaries of innovation while maintaining unparalleled quality standards. One of the most remarkable advantages of CNC machining is its repeatability. Every cut and hole can be replicated with exact consistency, reducing human error and minimizing waste. This consistency is crucial for industries where tolerances are tight and every micrometer counts.

The grooves, cuts, and holes produced through CNC technology exhibit smooth finishes and sharp edges, contributing to superior assembly and optimal performance of the final product. CNC machines operate using advanced software and computer-controlled mechanisms that translate digital designs into flawless physical parts. This seamless transition from design to product ensures that the original vision is accurately realized, enhancing overall project efficiency. Moreover, CNC precision machining significantly accelerates production timelines without sacrificing quality. The automated nature of CNC processes allows for faster turnaround times compared to manual methods, helping businesses meet tight deadlines while maintaining excellence. This efficiency translates into cost savings, as reduced rework and fewer defective parts lower production expenses. Additionally, CNC machining’s versatility enables it to handle a wide variety of materials from metals like aluminum, steel, and titanium to plastics and composites making it an indispensable tool across multiple sectors.

Beyond technical advantages, online cnc machining service fosters innovation by providing designers and engineers with the freedom to create intricate and complex geometries that would be difficult or impossible to achieve otherwise. This capability encourages creativity and drives product development forward, supporting advancements in technology and manufacturing processes. The high precision delivered by CNC machines also supports sustainable manufacturing practices by optimizing material usage and reducing waste, contributing positively to environmental goals. In summary, CNC precision machining is a cornerstone of quality manufacturing, delivering unmatched accuracy with every cut, hole, or groove. Its combination of repeatability, speed, versatility, and innovation enables manufacturers to consistently produce superior parts that meet exacting standards. As industries continue to evolve, CNC machining remains a vital technology that guarantees excellence and drives progress, ensuring that every component performs at its best and every project achieves success.